1. the continuous conveyor, static measurement, with the cumulative quantitative or quantitative batch mode selectable.

2. fully enclosed structure weighing, fast, stable and reliable.

3. strict surface treatment for a variety of environments.

4. special materials wear layer, improve equipment service life.

5. the pressure balancing system, to further improve the accuracy of the weighing.

6. monitoring, fault alarm and working condition.

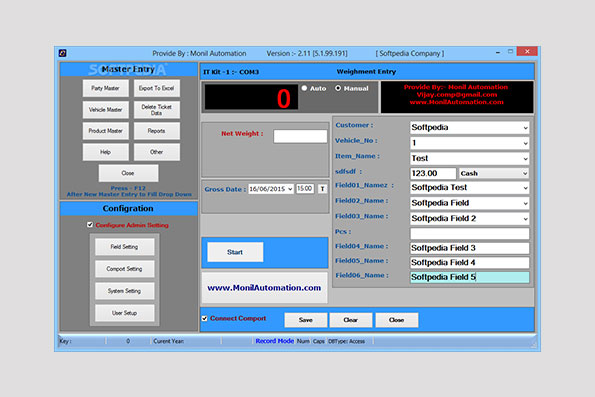

7. improved data management and report printing materials.

8. computer output interface.

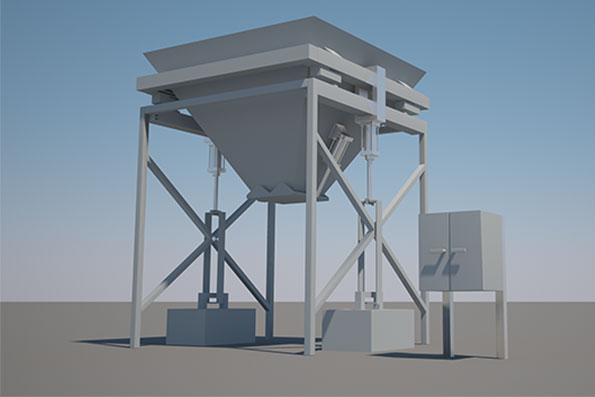

Bulk Weigher

Electronic bulk scales works – under the sensor is mounted on the amount of fighting, usually 3-4 sensors. The weight of the material converted into an electrical signal in the sensor, and display, recording and data processing after measurement circuit amplifier. New electronic bulk scales can be called gross, tare and net weight, with automatic zeroing and weighing data processing functions. Electronic bulk scales are widely used for automatic batching and weighing systems.

Suitable for continuous quantitative feeding, discharging or turning warehouse job control, widely used in flour, oil, brewing, food, grain storage, feed, chemicals, cement, coal, metallurgy, ports and other industries.

1. Power supply AC380V (50HZ), three-phase five-wire system, namely three-phase power, a ground phase, a phase zero line;

2. comprehensive error: better than 0.1%;

3. work: non-continuous measurement, material: coal;

4. remote, local, two modes of operation;

5. a single weight and accumulated weight display;

6. computer software functional description;

7. remote collection, most long-distance up to 1200 meters;

8. connected to the computer using RS485, economical, reliable, and accurate records of your production in every piece of data;

9. can be divided into shifts statistical weighing records;

10. weighing records stored in the computer database, can store up to 3 years of continuous weighing data;

11. the software administrator can assign permissions and rights software data query;

12. according to the time of the query data and statistics, check out the data or statistical data can be printed, or you can export Excel files;

13. the software has real-time feed, unloading animation scene actual engineering work, remote monitoring can play a role;

14. as needed, to provide data to the ERP software calls;

15. two hopper scales remote control uses 2 computers, 1 master 1 from;

16. remote operation function calibration weights

17. the configuration calibration weights (including cylinders, lifting chains, shackles)

18. the belt running status signal into the control system (in case the belt is not running, no discharge hopper scales and grab the red light prompts the operator, the alarm working)

19. the cylinder configuration of the detection signals to ensure the door switch in place to ensure accurate measurement.

20. Air source: 1.2MPA

可選配件